Need to fix your Harley Davidson Touring bike? Visit the Home page to get the complete factory service manual for your 2001-2009 Touring motorcycle and get it delivered to your computer in just seconds!

TOURING MANUALS AVAILABLE

2001 Harley Davidson Touring H-D Service Manual & 2001 H-D Electrical Diagnostics Manual for Harley Models: FLHTCUI Ultra Classic Electra Glide (2001), FLHTC/I Electra Glide Classic (2001), FLHT Electra Glide Standard (2001), FLTR/I Road Glide (2001), FLHRCI Road King Classic (2001), FLHR/I Road King (2001) and also contains the 2001 H-D FLT Police Model Service Manual Supplement and 2001 H-D FLTRSEI2 Service Manual Supplement.

2002 Harley Davidson Touring Service Manual & 2002 H-D Touring Electrical Diagnostic Manual for models: FLHTCUI Ultra Classic Electra Glide (2002), FLHTC/FLHTCI Electra Glide Classic (2002), FLHT Electra Glide Standard (2002), FLHTCUI Ultra Classic Electra Glide (2002), FLTR/I Road Glide (2002), FLHRCI Road King Classic (2002), FLHR Road King (2002), 2002 FLT Police Models Service Manual Supplement and 2002 FLTRSEI2 Model Service Manual Supplement.

2003 Harley Davidson Touring 2003 H-D Touring Service Manual, 2003 H-D Electrical Diagnostics Manual, 2003 H-D Police Model Service Manual Supplement and 2003 H-D FLHRSEI2 Service Manual Supplement for: 2003 Harley-Davidson FLHTCUI Ultra Classic- Electra Glide, 2003 Harley-Davidson FLHR/FLHRI Road King, 2003 Harley-Davidson FLHT Electra Glide -Standard, 2003 Harley-Davidson FLHRCI Road King -Classic, 2003 Harley-Davidson FLTR/FLTRI Road Glide, 2003 Harley-Davidson FLHTC/FLHTCI Electra Glide- Classic, 2003 FLHP, FLHTP and FLHRSEI2.

2004 Harley Touring Service Repair Manual & Electrical Diagnostics Manual For: 2004 H-D FLT Police Model, 2004 H-D FLHTCSE, FLHRS/I Road King Custom (2004), FLHTCUI Ultra Classic Electra Glide (2004), FLHTC/I Electra Glide Classic (2004), FLHT/I Electra Glide Standard (2004), FLTRI Road Glide (2004), FLHRCI Road King Classic (2004), FLHR/I Road King (2004).

2005 Harley Davidson Touring Service Repair Manual & Electrical Diagnostics Manual For: FLHRS/FLHRSI Road King Custom (2005) FLHTCUI Ultra Classic Electra Glide (2005), FLHTC/FLHTCI Electra Glide Classic (2005), FLHT/FLHTI Electra Glide Standard (2005), FLHTCUI Ultra Classic Electra Glide (2005), FLTRI Road Glide (2005), FLHRCI Road King Classic (2005), FLHR/FLHRI Road King (2005), 2005 H-D Touring Electrical Diagnostic Manual (800+ pages), 2005 FLT Police Models Service Manual Supplement and 2005 FLHTCSE 2 Model Service Manual Supplement.

2006 Harley Davidson Touring Motorcycle Service Manual for: 2006 FLHX Street Glide, 2006 FLHT Electra Glide Standard, 2006 FLHTC Electra Glide Classic, 2006 FLHTCU Electra Glide Ultra Classic, 2006 FLTR Road 2006 Glide, FLTRI Road Glide.

2007 Harley Davidson Touring Service Repair Manual & Electrical Diagnostics Manual For: (2007) FLHT Electra Glide Standard (2007), FLHR Road King (2007), FLHTC Electra Glide Classic (2007), FLHRS Road King Custom (2007), FLHTCU Ultra Classic Electra Glide (2007), FLHRC Road King Classic (2007), FLTR Road Glide (2007), FLHX Street Glide (2007).

2008 Harley Davidson Touring Motorcycle Factory Service Manual for: FLHT Electra Glide Standard, FLHR Road King, FLHTC Electra Glide Classic, FLHRC Road King Classic, FLHTCU Ultra Classic Electra Glide, FLHTCU ANV 105th Anniversary Ultra Classic Electra Glide, FLHRC ANV 105th Anniversary Road King Classic, FLTR Road Glide, FLHX Street Glide, 2008 FLT Police Models Service Manual Supplement, 2008 FLHTCUSE 3 Model Service Manual Supplement.

2009 Harley Davidson Touring Motorcycle Factory Service Manual for: 2009 FLHT Electra Glide, 2009 FLHTC/U Ultra Classic*Electra Glide with Side Car, 09 FLTR Road Glide, 09 FLHX Street Glide, 09 FLHR Road King Shrine, FLHRC Road King classic, FLHTC Electra Glide Classic.

Note: The information below should not be used as a reference as this is only a sample of information typicaly found in a service manual. For complete specifications for your year and model Touring motorcycle download the correct manual for your bike from the DOWNLOAD CENTER. Feel free to preview a sample to get an idea of what it looks like. Stop the guess work and get a manual!

The 4-cycle, 45°V 2, air-cooled 2 cylinder engine is a twin cams, chain driven with spring loaded tensioners. This engine is designed to use unleaded fuel. The engine lubrication system consists of a twin gerotor, dual scavenge, crank mounted and driven, internal oil pump, dry sump oil pump and 10 micron media, filtered between pump and engine with pressure 30-38 psi (207-262 kN/m2) at 2000 rpm and normal operating temperature of 230o F (110o C). The cylinders are numbered from front to rear; 1, 2 and refer to service manual on the firing order. When component part replacement is necessary, use the engine type and serial number to identify the correct part. Refer to your service manual for locations of serial stamp locations and for complete specifications of your year and model motorcycle.

SPECIFICATIONS

MANUFACTURING TOLERANCES

General

Number of cylinders 2

Type 4-cycle, 45°V 2, air-cooled

Torque - 86 ft-lbs (108.8 Nm) @ 3500 rpm, chrome duals exhaust

Bore - 3.75 in. (95.25 mm)

Stroke - 4.00 in. (101.6 mm)

Piston displacement - (approx.) 88 cu. in. (1450 cc)

Compression ratio - 9.0:1

Combustion chamber - 5.187 cu. in. (85 cc) bathtub

Cam system - Twin cams, chain driven with spring loaded tensioners

Max. sustained engine speed - 5500 rpm

Idle speed - 1000 rpm +/- 50

Weight -165 lbs (74.8 kg)

Ignition System

Type

Sequential, non waste spark, MAP-N control

Ignition timing: 1050 rpm (Hot Idle) 20o-30o

Spark plug size - 12 mm

Spark plug type Harley-Davidson - 6R12

Spark plug gap - 0.038-0.043 in. (0.97-1.09 mm)

Spark plug torque - 12-18 ft-lbs (16-24 Nm)

Oiling System

Pump - Twin gerotor, dual scavenge, crank mounted and driven, internal oil pump, dry sump

Pressure - 30-38 psi (207-262 kN/m 2 ) at 2000 rpm and normal operating temperature of 230o F (110o C)

Rocker Arm IN. MM

Shaft fit in bushing (loose) - 0.0005-0.0020 0.013-0.051

End clearance - 0.003-0.013 0.08-0.033

Bushing fit in rocker arm (tight) - 0.002-0.004 0.051-0.102

Filtration - 10 micron media, filtered between pump and engin.

Rocker Arm Shaft IN. MM

Shaft fit in rocker arm support plate (loose) - 0.0007-0.0022 0.018-0.056

Hydraulic Lifter IN. MM

Fit in crankcase (loose) - 0.0008-0.0020 0.02-0.05

Cylinder Head IN. MM

Valve guide in head (tight) - 0.0020-0.0033 .0060.051-0.084

Valve seat in head (tight) - 0.003-0.0045 0.076-0.114

Head gasket surface (flatness) - 0.006 0.0152

Valve IN. MM

Fit in guide: exhaust - 0.0015-0.0033 0.038-0.084

Fit in guide: intake - 0.0008-0.0026 0.020-0.066

Seat width - 0.040-0.062 1.02-1.58

Stem protrusion from cylinder head boss - 1.990-2.024 50.55-51.41

Valve Spring - Outer & Inner

Closed

72-92 lbs @ 1.751-1.848 in.

38-49 lbs @ 1.577-1.683 in.

33-42 kg @ 44.45-46.9 mm

17-22 kg @ 40.1-42.8 mm

Open

183-207 lbs @ 1.282-1.378 in.

98-112 lbs @ 1.107-1.213 in.

83-94 kg @ 32.6-35.0 mm

44-51 kg @ 28.1-30.8 mm

Free length

2.105-2.177 in. 1.926-1.996 in.

53.47-55.3 mm 48.9-50.7 mm

Piston IN. MM

Fit in cylinder 0.0006-0.0017 0.015-0.043

Ring end gap:

Top compression ring

2nd compression ring - 0.014-0.024 - 0.36-0.61

Oil control ring - 0.010-0.050 - 0.25-1.27

Ring side clearance:

Top compression ring - 0.010-0.020 - 0.25-0.51

2nd compression ring - 0.0012-0.0037 - 0.030-0.094

Oil control ring - 0.030-0.094 - 0.079-0.23

0.0012-0.0037

0.0031-0.0091

Piston pin fit (loose) 0.0003-0.0005 0.008- 0.013

Connecting Rod IN. MM

Piston pin fit (loose) 0.0003-0.0007 0.008-0.018

Side play between flywheels - 0.005-0.015 0.13-0.38

Connecting rod to crankpin (loose) 0.0004-0.0017 0.0102-0.0432

Flywheel IN. MM

Runout (flywheels at rim) - 0.000-0.010 0.0-0.25

Runout (shaft at flywheel) - 0.000-0.002 0.0-0.05

End play 0.001-0.005 0.03-0.13

Sprocket Shaft (Timken) Bearing IN. MM

Cup fit in crankcase (tight) - 0.003-0.005 0.08-0.13

Cone fit on shaft (tight) - 0.005-0.0015 0.013-0.038

Crankshaft (Roller) Bearing IN. MM

Roller bearing fit (loose) - 0.0002-0.0015 0.005-0.038

Crankshaft runout - 0.0-0.003 0.0-0.076

Bearing fit in crankcase (tight) - 0.0018-0.0021 0.046-0.053

Bearing inner race on crankshaft (tight) - 0.0009-0.0012 0.023-0.031

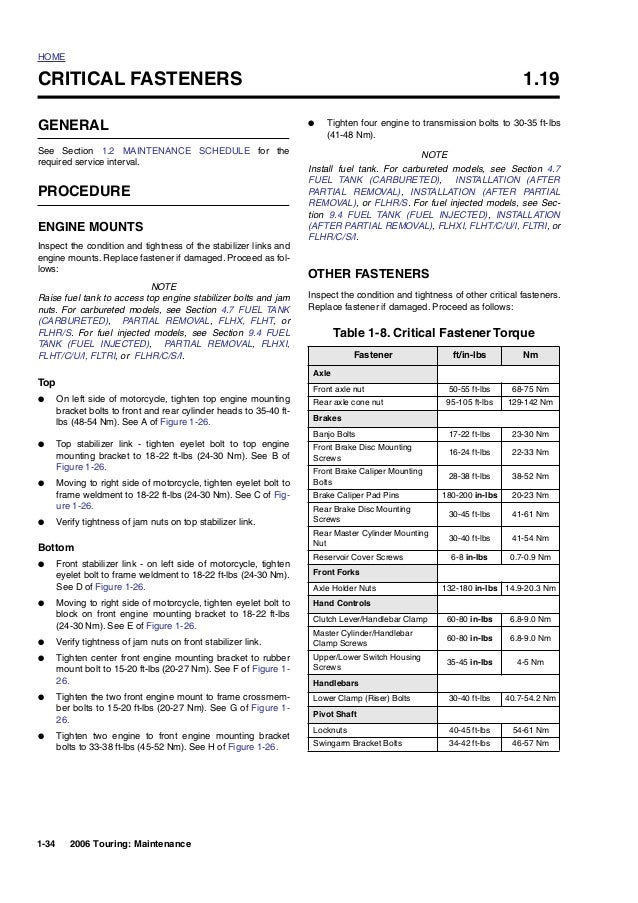

Item ft/in-lbs NM

Breather assembly bolts 90-120

in-lbs - 10-14 Nm

Cam cover screws - 125-155 in-lbs - 14-18 Nm

Cam cover plate screws - 20-30 in-lbs 2.3-3.4 Nm

Cam support plate screws - 90-120 in-lbs 10-14 Nm

Bearing retainer plate screws - 20-30 in-lbs - 2-3 Nm

Crank sprocket flange bolt - 15 ft-lbs,

loosen one full turn, 24 ft-lbs 20.3 Nm, loosen one full turn, 32.5 Nm

Primary cam sprocket flange bolt - 15 ft-lbs,

loosen one full turn, 34 ft-lbs - 20.3 Nm, loosen one full turn, 46.1 Nm

Crank position sensor screw - 90-120 in-lbs - 10.2-13.6 Nm

Piston jet screws 25-35in-lbs - 2.8-4.0 Nm

Transmission housing to crankcase bolts - 15 ft-lbs, 30-35 ft-lbs - 20 Nm, 41-48 Nm

Crankcase to front engine mounting bracket bolts - 33-38 ft-lbs 45-52 Nm

Crankcase bolts - 10 ft-lbs, 15-19 ft-lbs - 14 Nm, 20-26 Nm

Cylinder head bolts - 7-9 ft-lbs, 12-14 ft-lbs + 90o turn 9-12 Nm,16-19 Nm + 90o turn

Cylinder studs 10-20 ft-lbs 14-27 Nm

Engine oil drain plug 14-21 ft-lbs 19-28 Nm

Lifter cover screws - 90-120 in-lbs - 10-14 Nm

Oil pan screws - 84-108in-lbs - 9-12 Nm

Oil filter - 1/2-3/4 turn after gasket contact

Oil filter mount - 130-150 in-lbs - 15-17 Nm

Crankcase oil fittings/plugs - 10-14 ft-lbs 14-19 Nm

Oil hose cover screws - 84-108 in-lbs - 10-12 Nm

Oil pressure sending unit - 96-120 in-lbs 11-14 Nm

Rocker arm support - plate bolts - 18-22 ft-lbs 24-30 Nm

Rocker cover bolts 15-18 ft-lbs 20-24 Nm

Rocker housing bolts - 10-14 ft-lbs 14-19 Nm

Spark plugs - 12-18 ft-lbs 16-24 Nm

Stator screws - 30-40 in-lbs - 4-5 Nm

Upper engine mounting bracket:

To cylinder heads - 28-35 ft-lbs - 38-48 Nm

To top stabilizer link - 18-22 ft-lbs - 24-30 Nm

Engine sensor harness clip screws to crankcase - 25-35 in-lbs - 2.8-4.0 Nm

Engine temperature sensor - 10-15 ft-lbs 14-20 Nm

Intake flange adapter screws - 96-144 - in-lbs - 10.9-16.3 Nm

Exhaust flange adapter screws - 60-80 - in-lbs - 6.8-9.0 Nm